Fully Automatic Rolling Shutter Door Machine

Product Description

Rolling Shutter Door Machine is a specialized roll forming equipment designed to produce high-quality shutter slats for commercial, industrial, and residential applications. This machine supports a wide range of materials such as galvanized steel, pre-painted steel, and aluminum, and can be customized to produce various shutter profiles based on client requirements.

Equipped with precision rollers, automatic cutting, punching, and embossing systems, the machine ensures smooth, high-speed production with consistent results. PLC and touch screen controls allow for easy operation, quick adjustments, and minimal downtime. Optional servo tracking cutter and hydraulic decoiler systems further enhance automation and efficiency.

Ideal for manufacturing rolling doors used in shops, warehouses, garages, and industrial buildings, this machine delivers strong, secure slats with excellent aesthetics. Backed by a manufacturer with over 30 years of experience, it is a reliable solution for both mass production and custom orders.

Profile Drawing

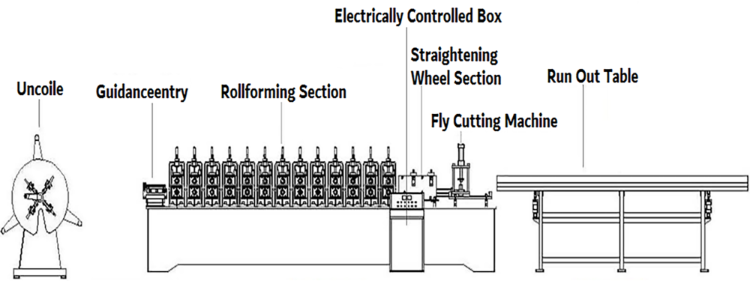

Working Flow

Product Details

Machine Parameters

|

Name

|

Fully Automatic Rolling Shutter Door Machine

|

|

Suitable to process

|

Galvanized steel strips/cold rolled strips

|

|

Roller

|

16Rows

|

|

Dimensions

|

10*1.2*1.5m

|

|

Motor Power

|

5kw

|

|

Pump Station Motor

|

5kw

|

|

Thickness of the plate

|

0.3mm-0.8mm

|

|

Productivity

|

10-15m/min

|

|

Material of the cutting blade

|

Cr12MoV,Quenched treatment 58ºC-60ºC

|

|

Diameter of the roller

|

85mm

|

|

Weight

|

About 5000Kgs

|

|

Main structure of the machine

|

300 H Beams and arch structure

|

|

Voltage

|

380V 50Hz 3phases or as customer’s need

|

|

Control system

|

PLC control

|

|

Drive mode

|

Motor driver

|

|

Rolling materials

|

GCr15(bearing steel)hard chrome plated after heat treatment

|

|

Length Tolerance

|

±1mm

|

|

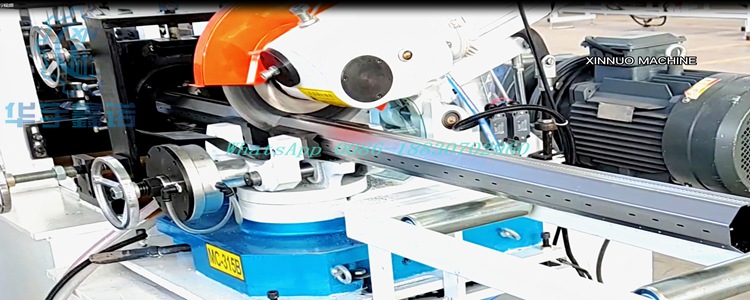

Type of cutting

|

Length-set cutting Guiding pipe Hydraulic cutter Each side one Oil cylinder |