Hat&C Shaped Steel Forming Machine

Product Description

Hat & C Shaped Steel Forming Machine is a versatile roll forming solution designed to produce both top hat channels and C-shaped profiles with a single machine. This dual-profile capability allows users to switch between two popular framing types without the need for additional equipment—saving cost, space, and setup time.

Engineered for high precision and efficiency, the machine is equipped with advanced roller systems, automated punching, servo tracking cutting, and intelligent PLC control for seamless operation. It supports quick profile changes, allowing flexible production tailored to various installation needs in light steel framing, ceiling systems, partition walls, and modular buildings.

Whether you're fabricating structural support components or interior framing solutions, this machine delivers consistent quality, high-speed output, and unmatched adaptability—making it a perfect choice for manufacturers who demand performance and versatility in one solution.

Profile Drawing

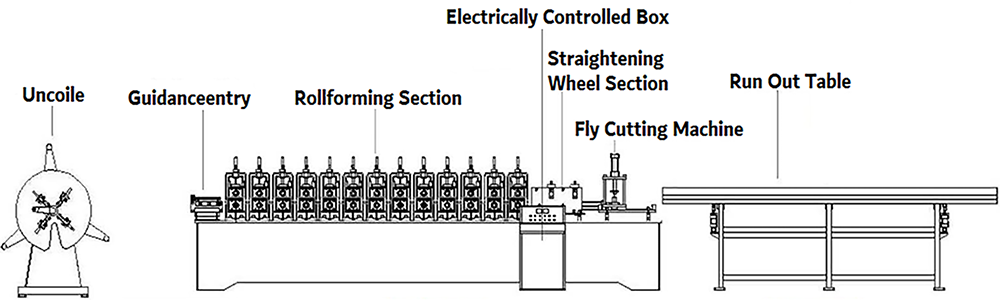

Working Flow

Product Details

Machine Parameters

|

Name

|

Hat&C Shaped Steel Forming Machine

|

|

Suitable to process

|

Galvanized steel strips/cold rolled strips

|

|

Roller

|

20-28Rows

|

|

Dimensions

|

12*2.0*1.5m

|

|

Motor Power

|

11Kw*2

|

|

Pump Station Motor

|

7.5Kw

|

|

Thickness of the plate

|

1.0mm-3.0mm

|

|

Productivity

|

10-50m/min

|

|

Material of the cutting blade

|

Cr12MoV,Quenched treatment 58ºC-60ºC

|

|

Diameter of the roller

|

95mm

|

|

Weight

|

About 20000Kgs

|

|

Main structure of the machine

|

450 H Beams and arch structure

|

|

Voltage

|

380V 50Hz 3phases or as customer’s need

|

|

Control system

|

PLC control (Delta) or as customer’s need

|

|

Drive mode

|

Motor driver

|

|

Touch screen

|

Delta or as customer’s need

|

|

Rolling materials

|

GCr15(bearing steel)hard chrome plated after heat treatment

|

|

Length Tolerance

|

±1mm

|

|

Type of cutting

|

Length-set cutting Guiding pipe Hydraulic cutter Each side one Oil cylinder |

Prodcut Application