Photovoltaic bracket equipment, to achieve automatic translation operation, compatible with multiple models of production needs. The equipment is equipped with hydraulic punching system to ensure the machining accuracy. At the same time, the automatic palletizing function is integrated to significantly improve production efficiency. The equipment can also easily cope with the production of stainless steel material processing, showing its wide range of material adaptability.

Analysis of photovoltaic bracket equipment:

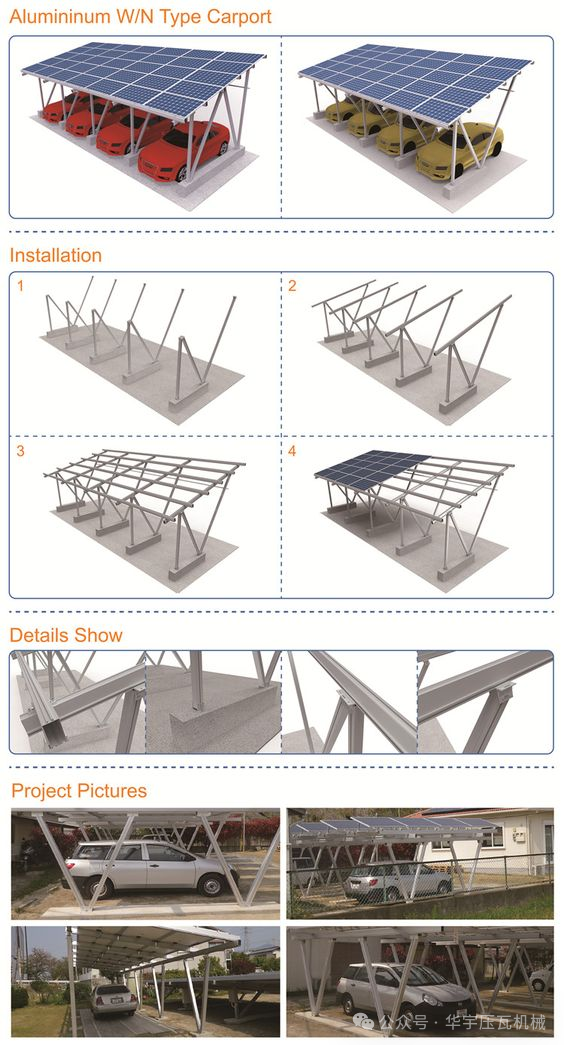

Firm support and orientation: As the cornerstone of the photovoltaics system, the primary task of the photovoltaic bracket is to firmly support the photovoltaic panel, ensuring its stability and orientation in various installation environments such as the ground and roof, precisely capture the sun's energy. Efficiency improvement and power generation optimization: Through the designed installation angle and direction adjustment mechanism, the photovoltaic bracket helps the photovoltaic panel to receive solar radiation, which significantly improves the overall power generation efficiency of the photovoltaic system. Security guard, resist challenges: Corrosion-resistant materials, photovoltaic brackets can effectively resist adverse weather conditions, such as strong winds, snow, etc. , for the safe and stable operation of photovoltaic systems escort. Various installation methods: From ground type (simple type, pile type fixed, foundation type) to roof type (plane, slope) , then to the fixed, double-sided/single-axis tracking rack system for suspension and large-scale photovoltaic power plants, to meet the installation needs in different scenarios. Choice of materials: Stainless steel, aluminum alloy, hot-dip galvanized steel and other materials, to ensure that the photovoltaic stent in harsh environments still maintain performance and durability.